Carbide Manufacturer

Precision Carbide Machining

25Years of carbide Expertise

Carbide Manufacturer(Powder to Finished Products)

Carbide Blanks and Precision Finished Products

Why choose us?

XBC is a leading technology provider in China’s carbide industry, specializing in high-quality carbide material manufacturing, processing, and applications.

We have comprehensive, high-precision equipment for everything from blank production to finished mold development.

Custom non-standard products are our specialty, used in hardware molds, new energy batteries, medical devices, the petroleum industry, semiconductor manufacturing, and automation.

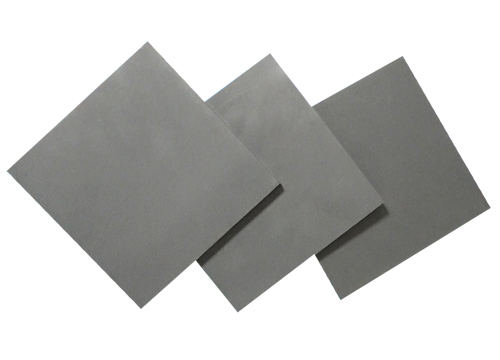

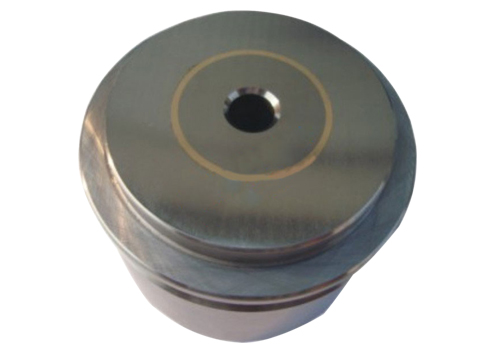

Cemented Carbide Blanks

We have spray dryer towers, 10MPa pressure sintering furnaces, fully automatic presses, 250T continuous extruders, and 150MPa dry bag isostatic presses. Products include rods, stamping plates, cold heading dies, and special wear parts.

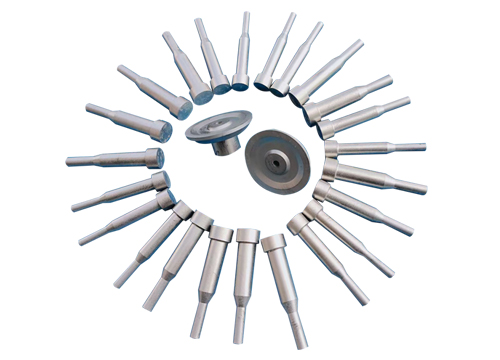

Cemented Carbide Preforms

Custom preforms with through holes, blind holes, tapered holes, stepped holes, threads, recesses, ejector pin holes, etc. can be machined according to drawings. These preforms closely match your final product, significantly reducing subsequent machining time and costs.

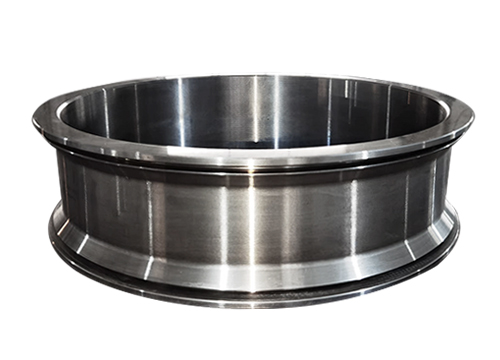

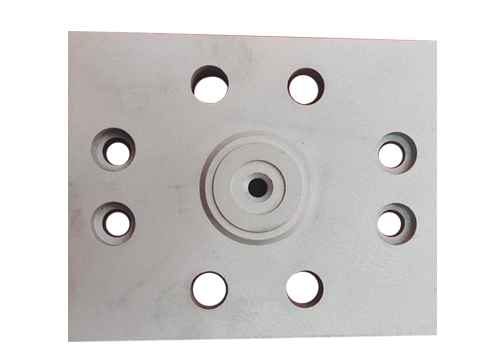

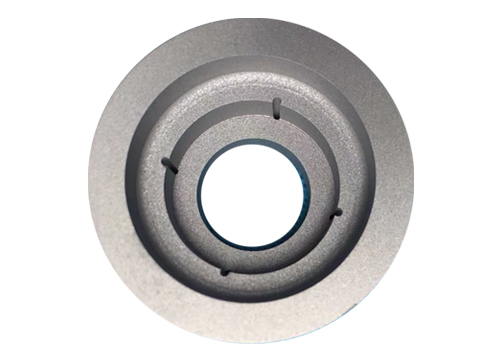

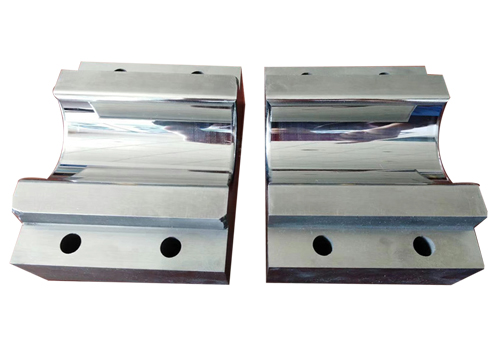

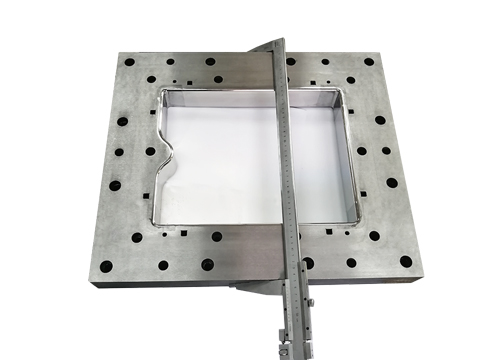

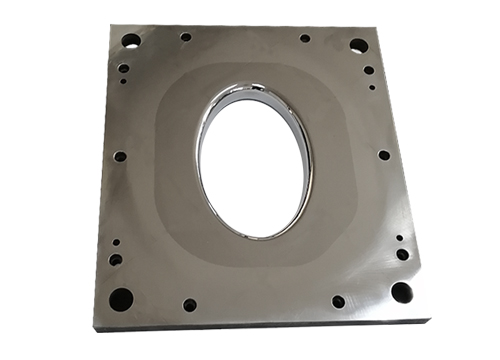

Cemented Carbide Mold

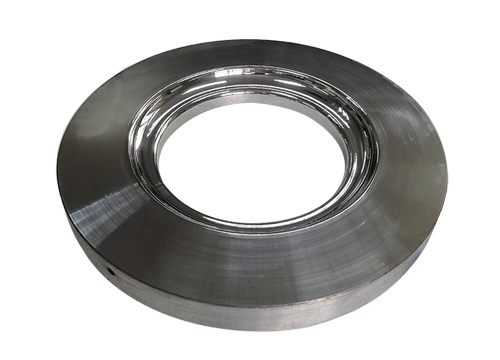

We have universal cylindrical grinders, internal grinders, surface grinders, EDM machining, and CNC machining centers. Our molds include drawing dies, forming dies, tube reducing dies, rollers, flanging wheels, and automotive wheel hub shaping dies.

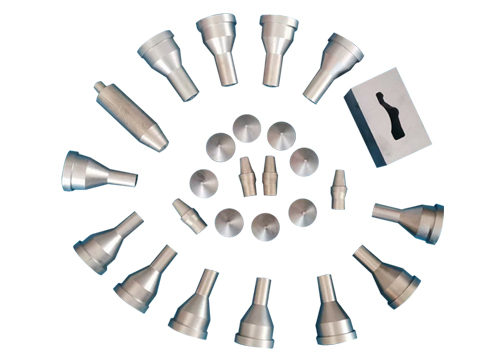

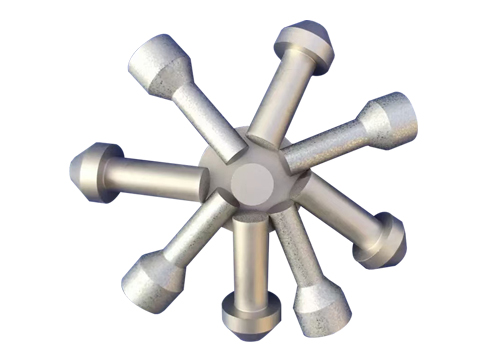

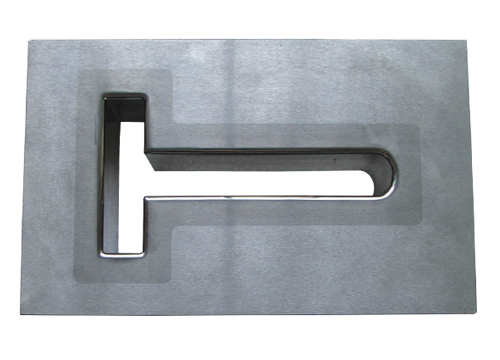

Carbide Precision Parts

We have Sodick wire EDM, precision surface grinders, precision centerless grinders, EDM machining, precision punch machines, and optical profile grinders. Dimensional tolerances can reach ±0.001, and surface roughness can achieve a mirror finish.

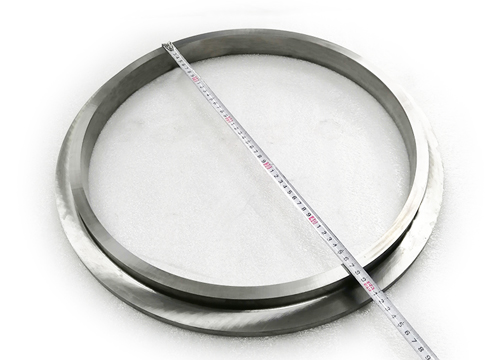

Large Carbide Products

Large carbide rings and carbide molds with diameters up to 820mm are our company's strengths. We can produce and process them with high quality and low cost.

High-Quality Carbide Materials and Preformed Blanks

Cemented Carbide Blanks

We have advanced production equipment and a complete production chain;

From powder mixing, pressing, presintering, blank shaping, HIP pressure sintering, cryogenic treatment to precision machining;

This integrated process enables us to control and produce cemented carbide materials suitable for various applications.

HIP Sintering Furnace

Metallographic Microscope

Carbide Blanks

Cemented Carbide Preforms

Cemented Carbide Mold

Sample Production Services

No Minimum Order Quantity

Fast Order Delivery

Cemented Carbide Preforms

Cemented Carbide Mold

Sample Production Services

No Minimum Order Quantity

Fast Order Delivery

Determine Working Conditions

Material Selection

Confirm Drawings

Manufacturing and processing

Product Delivery

Products

Perfect Solutions For Custom Carbide Products

Cemented Carbide●Grade

Select the Most Suitable Carbide Materials for Different Operating Conditions

Below is our grade chart for carbide materials developed for various industries and operating conditions, helping you find the right material to meet your needs.

BR Series

Carbide Rods

Using high-quality raw materials, advanced equipment, and sintering processes ensures material quality and stability. Select the specific grade based on the material being processed.

BHB Series

Materials for Electronic Progressive Dies

Rational process formulation for iron, copper, and stainless steel. High wear resistance effectively extends mold life.

BMB Series

Materials for Progressive Die of Motor

Rational process formulation for iron, copper, and stainless steel. High wear resistance effectively extends mold life.

BP Series

Powder Metallurgy Materials

We offer a range of specific grades for pressing copper, iron, tungsten carbide, ferrite, zirconia, and alumina powders. Please select the appropriate grade.

BHD Series

Cold Heading Materials

Special grain structure and additives enhance strength, allowing the material to withstand high impacts.

BM Series

Non-Magnetic Materials

Non-magnetic carbide offers high wear resistance, acid and alkali resistance, and high-temperature resistance, significantly improving efficiency compared to non-magnetic steel.

Cemented Carbide●Grade

Select the Most Suitable Carbide Materials for Different Operating Conditions

Below is our grade chart for carbide materials developed for various industries and operating conditions, helping you find the right material to meet your needs.

BR Series

Carbide Rods

Using high-quality raw materials, advanced equipment, and sintering processes ensures material quality and stability. Select the specific grade based on the material being processed.

BHB Series

Materials for Electronic Progressive Dies

Rational process formulation for iron, copper, and stainless steel. High wear resistance effectively extends mold life.

BMB Series

Materials for Progressive Die of Motor

Rational process formulation for iron, copper, and stainless steel. High wear resistance effectively extends mold life.

BP Series

Powder Metallurgy Materials

We offer a range of specific grades for pressing copper, iron, tungsten carbide, ferrite, zirconia, and alumina powders. Please select the appropriate grade.

BHD Series

Cold Heading Materials

Special grain structure and additives enhance strength, allowing the material to withstand high impacts.

BM Series

Non-Magnetic Materials

Non-magnetic carbide offers high wear resistance, acid and alkali resistance, and high-temperature resistance, significantly improving efficiency compared to non-magnetic steel.

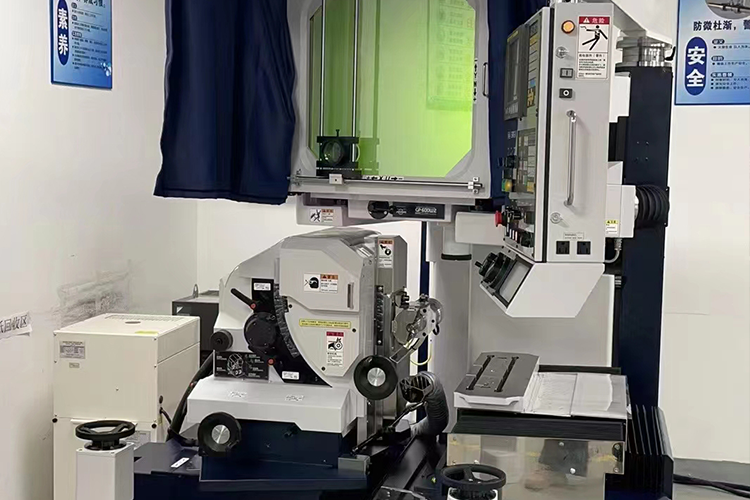

Precision Machining of Carbide

We have a complete set of advanced precision machining equipment, including PG optical profile grinders, universal cylindrical grinders, internal grinders, surface grinders, Sodick wire EDM, Sodick mirror EDM, and CNC machines. Dimensional accuracy can reach ±0.001 mm, and surface roughness can achieve a mirror finish.

Sodick Slow-Wire EDM

Optical Profile Grinder

-1.jpg)