Our Services

Carbide Manufacturer (Powder to Finished Products)

From blank production to finished product processing, we have a complete set of high-precision equipment. Custom non-standard products are our specialty, with a full production chain including powder mixing, pressing, presintering and shaping, HIP pressure sintering, carbide blank products, and precision machining. This integrated production chain allows us to control and produce carbide materials suitable for various fields. We specialize in providing perfect solutions for custom non-standard carbide products!

Cemented Carbide Materials

XBC boasts advanced production equipment, including spray dryer towers, 10MPa pressure sintering furnaces, fully automatic presses, 250T continuous extruders, and 150MPa dry bag isostatic presses. Our product line spans plates, rods, cold heading dies, stamping plates, and special wear parts. With this equipment and extensive production experience, we provide high-quality, diverse carbide products. Choose XBC for superior production equipment and professional expertise, helping you achieve greater success in various fields!

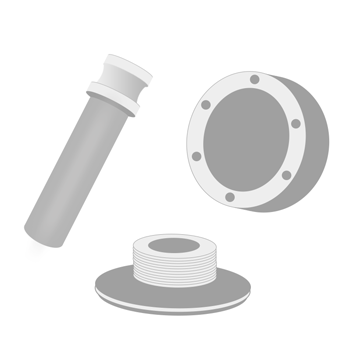

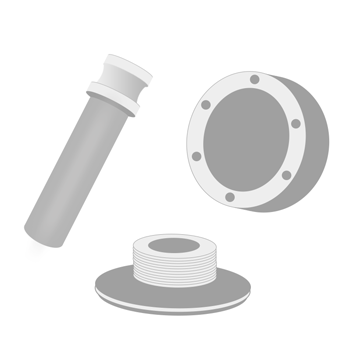

Cemented Carbide Preforms

We offer custom preforming services, covering through holes, blind holes, tapered holes, stepped holes, threads, recesses, ejector pin holes, and more. We also support processing according to provided drawings. Our custom services aim to closely match your product prototype, significantly reducing subsequent processing time and costs. Choose us for efficient and precise preforming solutions!

Cemented Carbide Preforms

We offer custom preforming services, covering through holes, blind holes, tapered holes, stepped holes, threads, recesses, ejector pin holes, and more. We also support processing according to provided drawings. Our custom services aim to closely match your product prototype, significantly reducing subsequent processing time and costs. Choose us for efficient and precise preforming solutions!

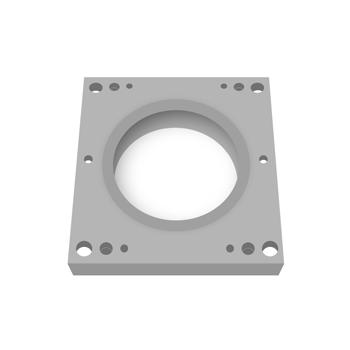

Cemented Carbide Molds

We have comprehensive equipment, including universal cylindrical grinders, internal grinders, surface grinders, EDM, and CNC machining centers. Our molds include drawing dies, forming dies, tube reducing dies, rollers, flanging wheels, and automotive wheel hub shaping dies. We also have advanced precision equipment like Sodick slow-wire EDM, precision surface grinders, centerless grinders, EDM, precision punch machines, and optical profile grinders, ensuring dimensional tolerances of ±0.001 and mirror surface finish. Choose us for top-notch equipment and technical support, ensuring precise and high-quality mold manufacturing.

Large Carbide Products

Our company specializes in producing large rings and alloy molds with diameters up to 820mm. We have advanced production equipment and technology to achieve high-quality, cost-effective mass production. By choosing us, you will receive efficient, high-quality services that meet your production needs while reducing costs.

Large Carbide Products

Our company specializes in producing large rings and alloy molds with diameters up to 820mm. We have advanced production equipment and technology to achieve high-quality, cost-effective mass production. By choosing us, you will receive efficient, high-quality services that meet your production needs while reducing costs.

+86137-7626-9629

Contact Us